Welcome back to our blog, your go-to source for innovative retail solutions that take your business to the next level. Stock rotation is an aspect of retail that often goes overlooked but can have a significant impact on your sales, product quality, and overall safety. That’s where pallet collars come into play.

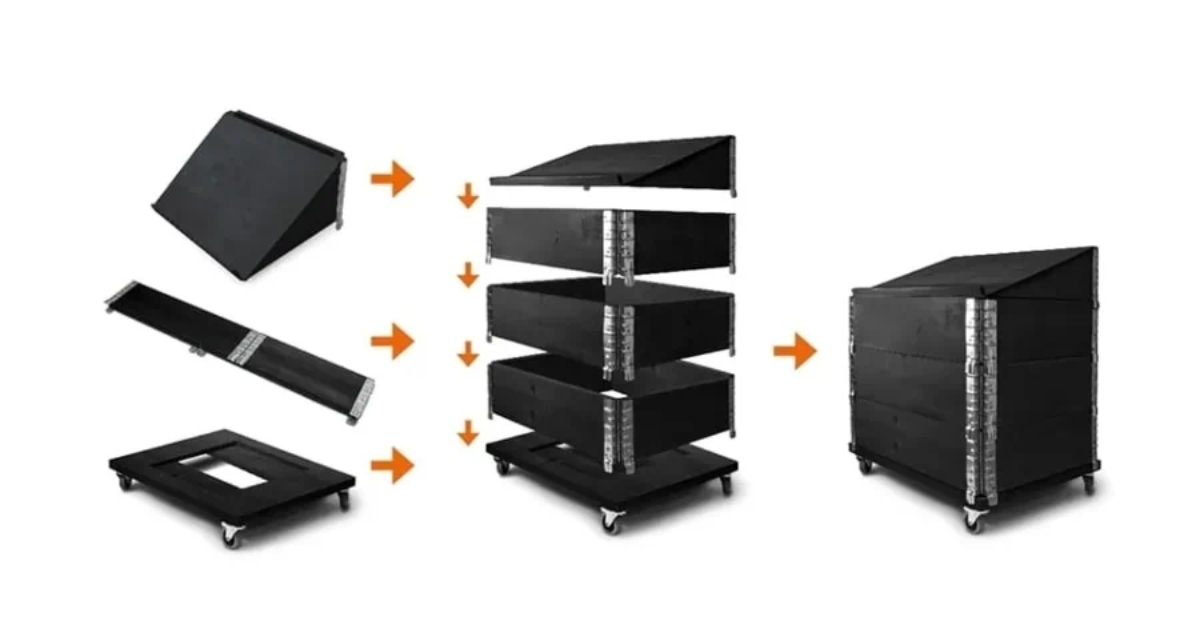

These versatile fixtures offer a powerful yet simple way to streamline your stock rotation. When combined with rolling platform trolleys, pallet collars not only facilitate a safe and efficient product placement solution but also become a game-changer in inventory management.

In this article let’s see how the use of pallet collars can help with efficient and also safe stock rotation. Let’s get started!

The importance of efficient stock rotation

Efficient stock rotation is not just about ensuring that your shelves are full. But it’s also about managing the shelf life of products and ensuring a smooth and safe workflow for your staff.

One of the key benefits of using pallet collars is preventing overstocking. Overstocking often leads to product spoilage and waste. With pallet collars, it’s easier to manage inventory levels and ensure a first-in, first-out (FIFO) rotation system. Then in turn it leads to fresher products on your shelves.

For example, pallet collars can be labelled and dated, allowing your staff to easily identify which items should be moved to the sales floor first.

Reducing handling risks with pallet collars

Handling merchandise is one of the less glamorous but essential parts of the retail business. It’s also one area where safety should never be compromised.

The beauty of pallet collars lies in their ability to minimize the risks associated with manual handling. When used in conjunction with rolling platform trolleys, staff can easily move large amounts of stock without straining themselves.

The stability of this combination also reduces the risk of stock falling or getting damaged, ensuring a safer work environment. And keep in mind that pallet display stands can do the same when used in retail settings.

So consider investing in pallet collars with adjustable heights to tailor your stock movement processes to different types of merchandise.

First-in, first-out – simplified by pallet collars

The first-in, first-out (FIFO) method of stock rotation is a retail best practice, but it can be challenging to implement without the right tools.

Pallet collars, especially when labeled or barcoded, make it a cinch to implement FIFO. You can customize your pallet collar setups to make it easy for your staff to identify which products need to go on the shelves first.

For example, setting up designated pallet collars for receiving new stock can ensure that older inventory is used before newer inventory. And that way, adhering to the FIFO principle effectively.

What’s trending – mobile and modular inventory solutions

In a fast-paced retail environment, flexibility is key. And when it comes to trending solutions for inventory management, mobility and modularity are at the top of the list.

The modernization of inventory practices is moving towards fully mobile and modular solutions, like the combination of pallet collars and rolling platform trolleys.

This duo serves as a fully mobile and safe product placement solution, allowing for easy adjustments based on seasonal inventory changes or promotional campaigns. Mobile solutions are particularly beneficial in large retail spaces where moving stock from storage to floor can be time-consuming.

In conclusion

Pallet collars are more than just an accessory in your retail space. They are a potent tool that can revolutionize your approach to stock rotation, safety, and efficiency.

And coupled with rolling platform trolleys, these fixtures offer a holistic solution to some of the most pressing challenges in retail today. With the emerging trends focusing on mobility and modularity, there’s never been a better time to rethink your inventory management strategies.

For efficiency related topics check out these articles too:

Stay tuned for more articles just like these!